Welcome to our Drive Gear Power Transmission Company!

We'are Open: Mon - Sat 8:00 - 18:00

- Call Us for help!

- +91 9422081933

- Mail Us

- enq@dgptransmission.co.in

- Reach Us

- Chikhali, Pune, Maharashtra, India

Our Product Range

-

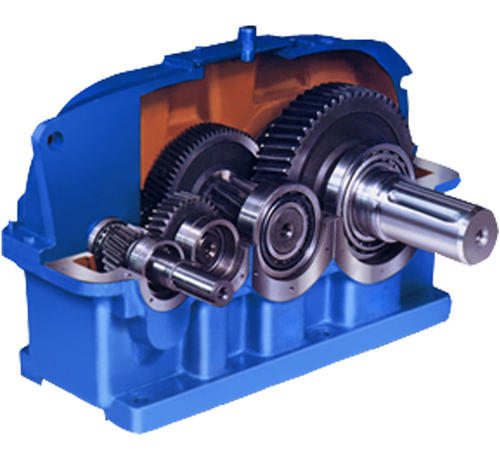

Gearbox